ASSEMBLY

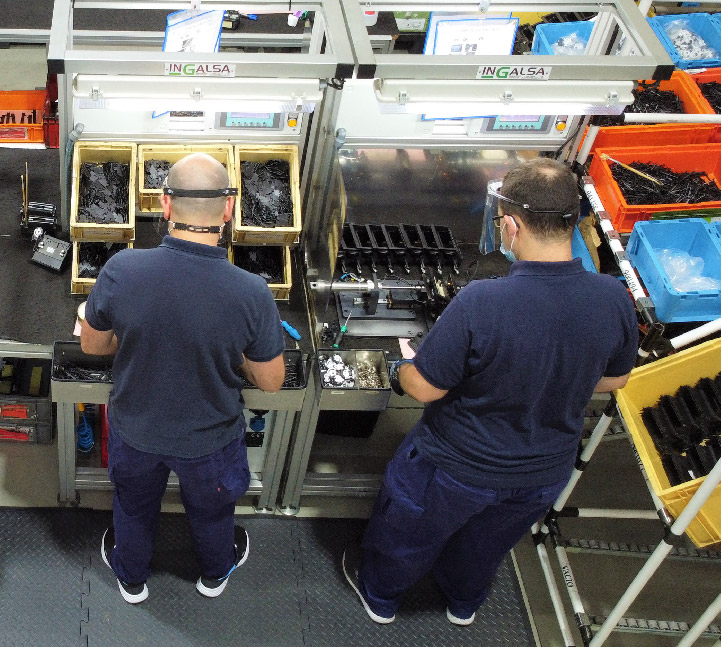

At INPLASOR, assembly is one of our most manual chain processes.

In this manufacture, plastic, metal and even painted and chrome components are assembled together to result in a finished part with the best quality.

We should underline our aerator assembly lines, where our operators work side by side, to manufacture parts that will be reviewed in a demanding final control. Appearance, assembly and noise reviews, among others, make quality assurance a reality in our production.

INPLASOR sells more than 150,000 assembled parts per year, which end up being placed in such well-known cars as the Citroën C4 Space Tourer (old Picasso), Renault Megane, Mercedes Vito or old Citroën Partner and Citroën Berlingo models.

In addition to this, small metal components such as staples, clips, or even gaskets and foams are assembled in our injection process during the cycle time of the machines.